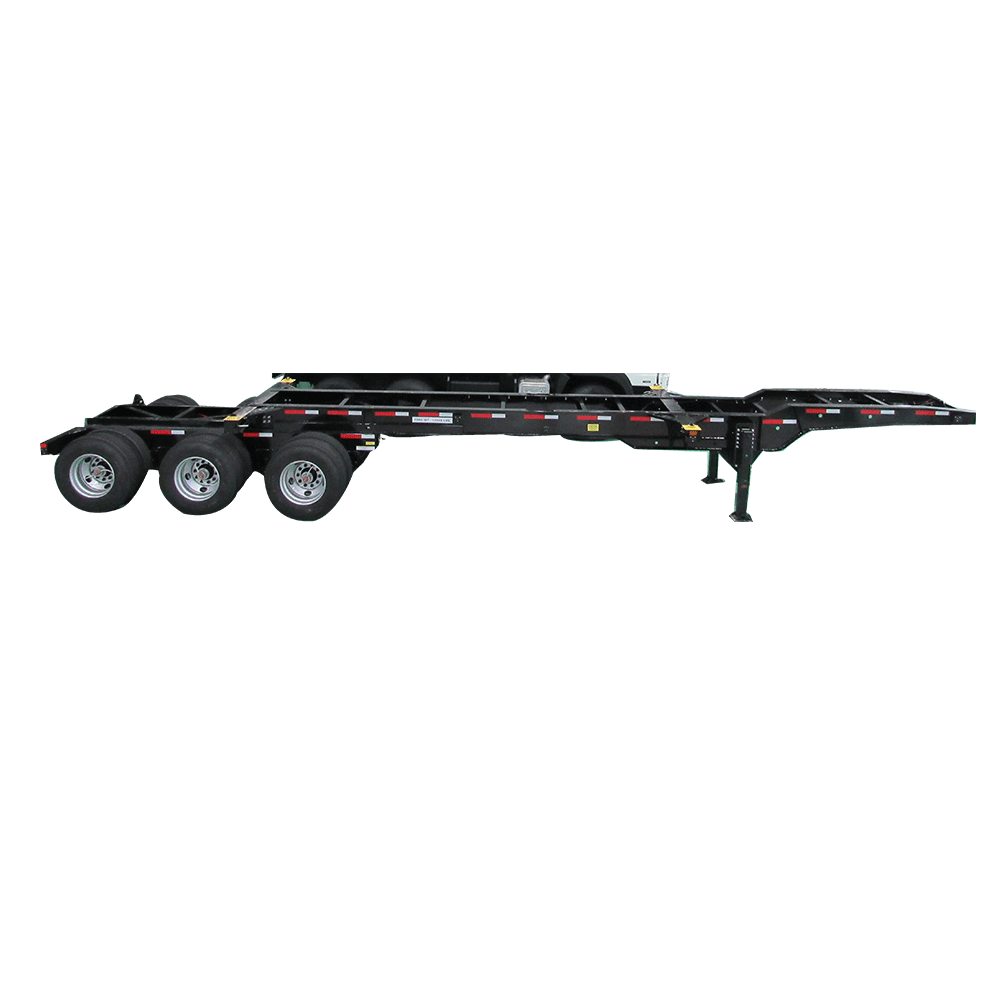

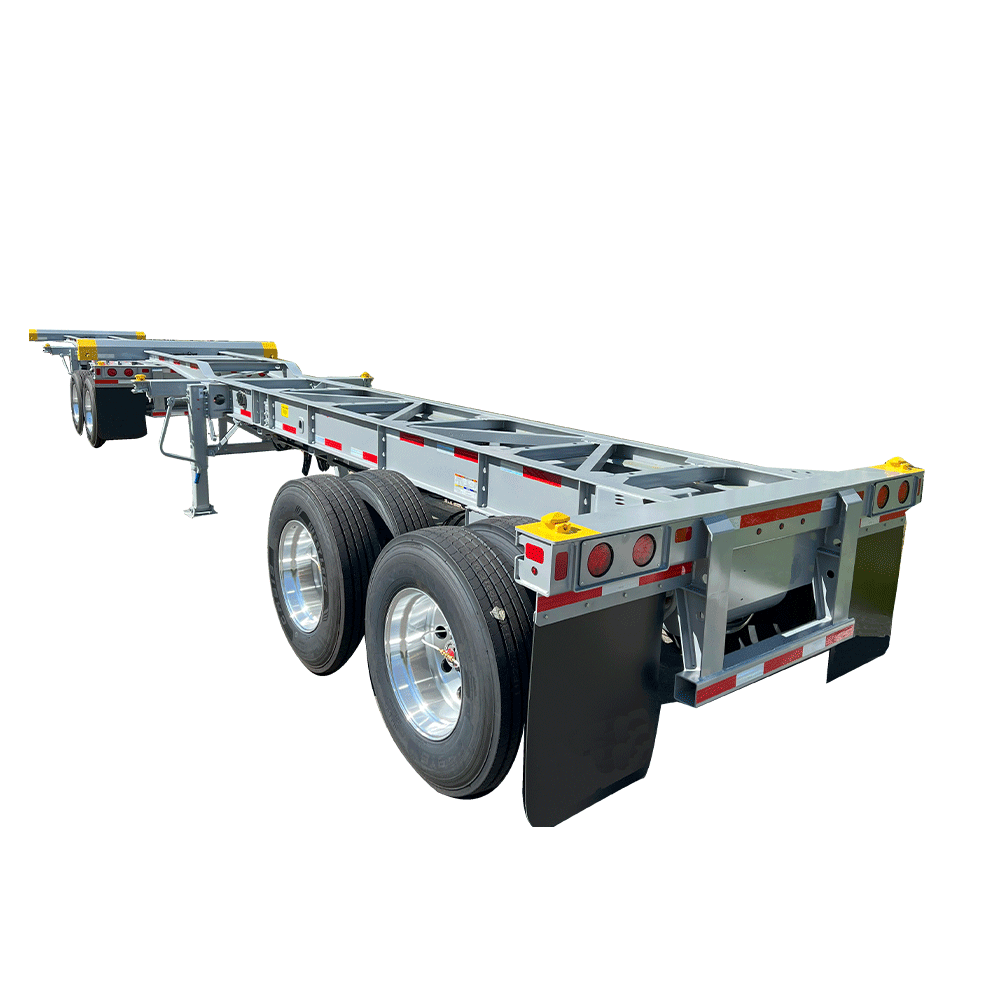

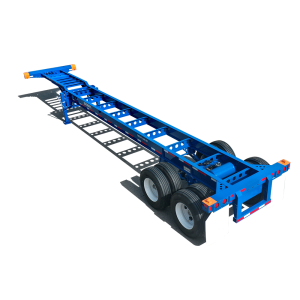

1. This chassis is designed for transporting a 20’ ISO container

This chassis meets all DOT, AAR, ANSI,TOFC, FMVSS, SAE and TTMA specifications.

2. General

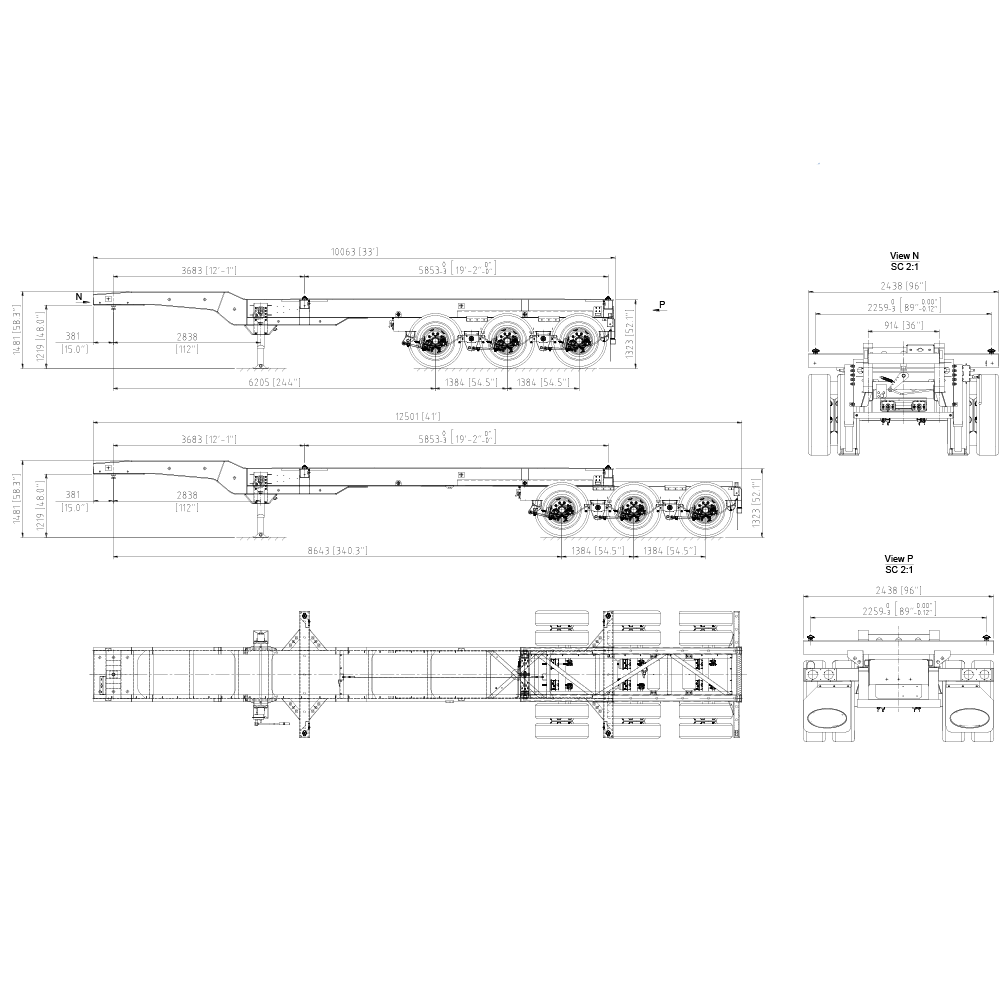

| Overall Length: | 33’ (retracted) or 41’ (extended) |

| Overall Width: | 96” |

| Fifth Wheel Height: | 48 ± 1” |

| Rear Deck Height | 52 ± 1” |

| Kingpin Location: | 15” |

| Landing gear location: | 112” (From the kingpin center) |

| Tridem location: | 16” (From rear face of rear bolster to rear axle center when extended) |

| Axle Spread: | 54.5” + 54.5” |

| Tare Weight: | 10,700 lbs ± 2% |

| Payload: | 67,200 lbs |

3. Steel Structure & Components

| Main beam: | Fabricated I-beam with high strength Grade 80 steel. |

| Cross member: | 3/16” thick x 3” wide x 9” deep channel with profiled bar type diagonal brace. |

| Slider beam: | 10” deep x 5” wide fabricated rectangular tube. |

| Upper Coupler: | 5/16” pick up plate with JOST 2” diameter square type kingpin per SAE standard, 380- 420 HB, with 2” water drain holes, design to be integrated with main frame through welding. |

| Bolsters: | 8” wide x 3/8” thick top plate with 7” wide x 6-3/4” deep x 5/16” thick “U” type bottom channel. |

| Rear Bumper: | 4” x 4” square tube step with taper “H” section vertical member. Bar is welded to uprights and main beam. |

| Twist Locks: | TOCA 905-130-000-90-LH/RH |

| Landing Gear: | AXN FW32E00J with 60,000 lbs capacity, 2-speed 17” travel with low “T” shoes. Crank handle is located on the driver’s side of the chassis. Pre-painted BLACK color. Landing gear brackets are welded on the main beam as the layout. |

| Suspension: | AXN 54.5” tri-axle, underslung configuration with high arch single leaf spring (360-00). Pre-painted BLACK color. |

| Axles: | AXN 5” round axles with 22500lb capacity; 71.5” track, Q+ 16.5”X7” 4707Q brake. Prepainted BLACK color. |

| 1.5-28 spline, HALDEX 5.5” automatic slack adjusters. | |

| Reserved PSI interface; Heat Sensing Labels. | |

| Axle Installation orientation: 90 degrees rear, Chambers DOWN (2 abs ready front and rear, 1 non abs mid per unit). | |

| Wheel end: | AXN Hub & Drum Assembly P/N H30-0647BFNTZ/H30-0647BFNZ, STEMCO 358-4009 Integrated Sentinel Grease Hub Cap,STEMCO seals and bearings.Spindle nut: STEMCO Pro-Torq P/N 447-4743. (5-year warranty wheelend). |

| Lubricant: | Petro Canada precision synthetic EP 00 semi fluid grease lubricant. |

| Wheels: | JINGU 22.5 x 8.25 10-stud hub-piloted wheels with 5 hand holes and with TR572 valve stem. Pre-painted white color. |

| Tires: | WESTLAKE 11R22.5-14PR, tubeless type. |

| Brake System: | SEALCO 110800 spring brake priority valve system and WABCO 4S/2M ABS system; PHILLIPS glad hand 12-0061 and 12-0081, 3/8” blue air tube for control and 3/8” red for supply. HALDEX Goldseal T30/30, 2.5” stroke brake chamber. FUWA air tanks. |

| Electrical: | PHILLIPS mold seal wiring harness, Reserved PSI and GPS connector. (10-year warranty)OPTRONICS LED lights (amp connections for S/T/T lights and .180 bullets for others). The theft proof design used for 4” LED lighting. |

| Electrical Receptacle | PHILLIPS 15-7292 zinc alloy material with solid pins. |

| Document Holder: | PHILLIPS 16-802. Installed on roadside near crank handle. |

| Conspicuity tape | “3M” brand. Installed per federal regulations. |

| Painting: | Abrasive blast of all metal surfaces – not less than SA-2.5 to achieve clean bare steel. Surface will be coated with electrophoresis primer and true acrylic aliphatic urethane topcoat. Color BLACK and at the corner painted YELLOW color. Total thickness not less than 80μm after dry membrane. Coating supplier: NOROO (7-year warranty) |

| Marking: | Customer configuration (includes Decal, layout, VIN, nameplate) |

| Hubodometer: | NONE |

| Tire Inflation System | NONE |

| Mud flaps | 24”x24”x1/4” white PVC mud flaps. |